Here’s all the info you need when it comes to thermal paste: What it’s for, and how to apply it to make sure your processor is properly cooled.

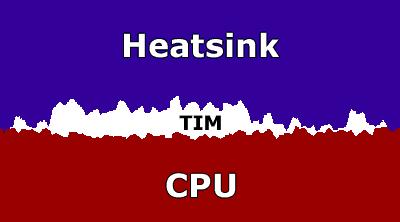

If you’ve delved into the world of PC building, you’ve no doubt heard about thermal paste. This material is also known as thermal grease, heat paste, CPU paste, thermal gel, and thermal interface material (TIM), among other names. Whatever you call it, the correct application of thermal paste is an important part of ensuring your CPU is operating properly.

That’s why it’s important to know not only how it works, but also how to correctly apply it when working with a CPU.

When Do You Need to Apply Thermal Paste?

Thermal transfer material is used when installing any cooling solution. When people think about thermal paste in the context of building a PC, they’re probably referring to the process of installing a CPU cooler. When you buy a graphics card, for example, the thermal solution is already integrated. You don’t usually have to worry about installing a cooler onto a GPU, unless you are interested in aftermarket solutions like custom liquid cooling. With a CPU cooler, you have the option to choose the one you want, but that means you’ll usually need to install it yourself.

Terms You Need to Know

In order to properly explain how thermal paste functions, it’s worth defining some of the terms we will be using.

Central Processing Unit (CPU) - The information processing center of a PC. It executes all operational instructions and sends instructions to the other hardware in the computer. If the computer is a body, then the CPU is the brain, and it is absolutely critical to the functioning of any PC. Modern CPUs execute a high volume of operations per second, and this generates heat. In order for a CPU to operate at peak efficiency, it needs to be properly cooled, usually with a cooling apparatus designed just for this purpose. This is where thermal paste becomes important. If you'd like to learn more about how a CPU is made, you can read more about the manufacturing process.

Integrated Heat Spreader (IHS) - The metal “lid” of the CPU. This serves as a heat sink designed to distribute heat from the processor itself to a CPU cooler, as well as provide protection to the processor inside. This is the part of the CPU that is still exposed after being installed in a motherboard, and is the surface to which you apply thermal paste.

CPU Cooler - The device that keeps your CPU running at optimal temperatures. CPU coolers usually use air or liquid to relocate the heat created by the operation of the CPU.

Base-Plate - The metal base of an air-cooler that attaches to the IHS of the CPU. This design allows the transfer of heat through convection to the fins of the heat sink, where it can then be redistributed with a fan.

Waterblock - The apparatus that attaches to the IHS when using an All-in-One (AIO) liquid cooler or a custom cooling loop. It transfers heat from the IHS to the heat transfer fluid, which then relocates that heat to be redistributed by fans at a radiator.

Thermal Paste - A silvery-gray substance that you apply to a processor before installing a cooling solution. It allows for an efficient transfer of heat from the IHS of the processor to the base plate or water block of the CPU cooler that is designed to dissipate that heat.

Why Do You Need Thermal Paste?

Even though the metal base of the CPU cooler and the IHS of the CPU look smooth to the naked eye, these metal plates have microscopic imperfections that can result in poor heat transfer. The two surfaces aren’t in full contact due to those imperfections, so thermal paste fills in those air gaps, allowing for a more efficient transfer of heat.

Simply put, thermal paste helps your CPU cooler do its job, and a cooler CPU means less potential performance issues, such as throttling.

Important Preparations for Thermal Paste Application

Most processors require some sort of thermal solution to properly operate at peak efficiency, but the process of installing a CPU cooler in a PC is unique.

Every CPU cooler needs thermal paste, but many have it pre-applied, which simplifies the installation process. To find out if you have pre-applied paste, check the bottom of the base plate or water block of your CPU cooler that attaches to the CPU. If the silver paste is already there, you don’t need to add any more during the installation process.

A few things to keep in mind before starting:

- Make sure that the CPU is clean, and that there isn’t any old thermal paste on it. If there is, carefully remove the old paste from the lid of the CPU with isopropyl alcohol and a microfiber cloth or paper towel that doesn’t shed, and let it dry before continuing.

- Before you start applying the thermal paste, make sure the rest of your CPU cooler is ready to install. Consult the instructions, ensure that every step has been completed up to attaching the CPU cooler, and make sure you have any necessary tools close at hand.

Situations to Avoid:

- Make sure to use the correct amount of thermal paste, which is roughly the size of a pea or a grain of rice. An insufficient amount might not cover the surface area needed in order to be effective. Too much reduces the efficacy of the paste, due to the metal surfaces being too far apart, and also risks spilling out onto the motherboard during installation.

- It might be tempting to spread the thermal paste onto the CPU yourself. We recommend letting the pressure from the base-plate or waterblock being installed do it for you. Incorrect manual application can cause air bubbles to form in the paste, which can negatively impact the thermal conductivity.

- Reusing paste can also cause air bubbles to form. If a problem occurs during the installation process and you have to remove the CPU cooler, you should completely clean off all paste as mentioned above, then try again with a fresh application. If you absolutely need to reuse an application — while waiting for replacement paste, for example — you can, but keep in mind this is a short-term solution, and that we recommend a proper reapplication before long-term use of your CPU cooler.

How to Apply Thermal Paste - Step by Step

We recommend reading through this entire section before beginning the installation process, so you know what to expect, and can plan ahead.

- Read all relevant instructions before starting. This includes those that come with your CPU cooler and thermal paste. Every brand of thermal paste and CPU cooler is a little different, and knowing the particulars of yours before starting will help the process go smoother.

- Apply thermal paste onto the center of the CPU’s IHS. (If you already have thermal paste pre-applied on your cooler, you can skip this step.) You only need to apply a small amount — roughly the size of a grain of rice or a pea — onto the center of the integrated heat spreader.

- Install CPU cooler.Use light, top-down pressure to place the base-plate or waterblock of your cooler onto the CPU, and hold that pressure while attaching the cooler to the mounting mechanism. You’ll want to use enough force to keep the cooler from sliding, and to evenly distribute the thermal paste, but you don’t want to push hard enough to bow the motherboard or damage the CPU. Keep the cooler in place as you attach it to the motherboard in a diagonal pattern, securing the screws (assuming you are using a screw mechanism) as if you were drawing an “X” with them. Do not fully tighten the screws until you have attached all four, then turn each a few times before moving on to the next in order to ensure even pressure.

- Double-check your work.Once the base-plate or water-block of the CPU cooler is firmly attached, check your work to make sure everything looks correct. There shouldn’t be any thermal paste spilling over the edges of the CPU, or anywhere on the motherboard. If there is, it means you used too much paste, and should clean it off with alcohol and start the process again. If everything looks clean and the cooler doesn’t move when you touch it, then congratulations! You’ve completed this critical step.

Replace Thermal Paste?

In most cases, you shouldn’t need to reapply more than once every few years, though you should replace your paste if you remove your cooler for any reason. You may also want to consider reapplying thermal paste if you find your CPU temperatures are climbing.

If in doubt, consult the thermal paste manufacturer, and follow their recommendations.

Stay Cool Out There

Thermal paste may not be discussed as frequently as gaming hardware like the CPU or GPU, but it is an essential part of keeping those components functioning at their best. Knowing how to properly apply thermal paste can help to make sure you’re getting the best performance from your CPU.